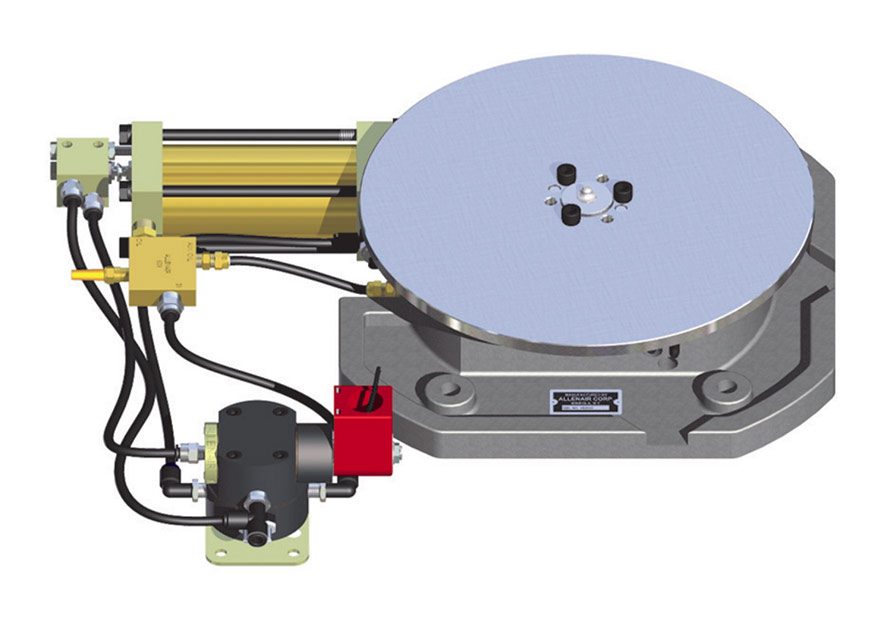

Rotary Tables

Allenair Rotary Index Tables

As more assembly processes move to automation, the need for rotary index tables increases. Allenair has been building pneumatically driven index tables for over 50 years. Our tables are designed to have precision indexing and unsurpassed accuracy and performance, while still being easy to maintain and repair due to the simplicity of the pneumatically driven design.

The rotary tables are built to completely enclose all working components to ensure all dust and other particles are kept out. All wearable components have been hardened to ensure life to exceed your equipment and bronze and roller bearings used in those areas where needed. The table surface and indexing mechanism are precision ground to make sure your equipment gets the highest level of repeatability. All of the tables come with integrated flow controls to help you get the optimal indexing speed for your specific application. Our tables are available in a few different sizes and can be ordered with a wide range of index increments.

The rotary tables are built to completely enclose all working components to ensure all dust and other particles are kept out. All wearable components have been hardened to ensure life to exceed your equipment and bronze and roller bearings used in those areas where needed. The table surface and indexing mechanism are precision ground to make sure your equipment gets the highest level of repeatability. All of the tables come with integrated flow controls to help you get the optimal indexing speed for your specific application. Our tables are available in a few different sizes and can be ordered with a wide range of index increments.

All of our tables are available in a basic design without a control valve, or leave it to the experts and chose from our various valve control options. Call today to let our team help you choose the best option for your design.